Specialty Plumbing

Restoring access.

Maintenance & Inspection

Caliber Restoration offers inspection, preventative maintenance, annual maintenance, and potentially (under contract) emergency services for prospective and existing clients.

We offer video inspection and digital location services throughout the range of diameters listed above. For small diameter pipelines (<8’), this will be primarily achieved via various sized lateral (push) cameras. This equipment allows us to broadcast to multiple devices (monitors, iPads, phones, etc.) if clients and/or a larger team is present, and allows us to record CCTV video footage, still photos, etc. and immediately publish, label, and share from site via email or SMS Text message.

The equipment has integrated sondes which emit a radio frequency traceable by one of our digital receivers, relaying location information, depth, percentage slope, etc. This information can be marked out on site with temporary marking paint or tape (or even recorded via GPS) and mapped out for client along with a marked up photoset and report.

Preventative & Annual Maintenance

De-Scaling

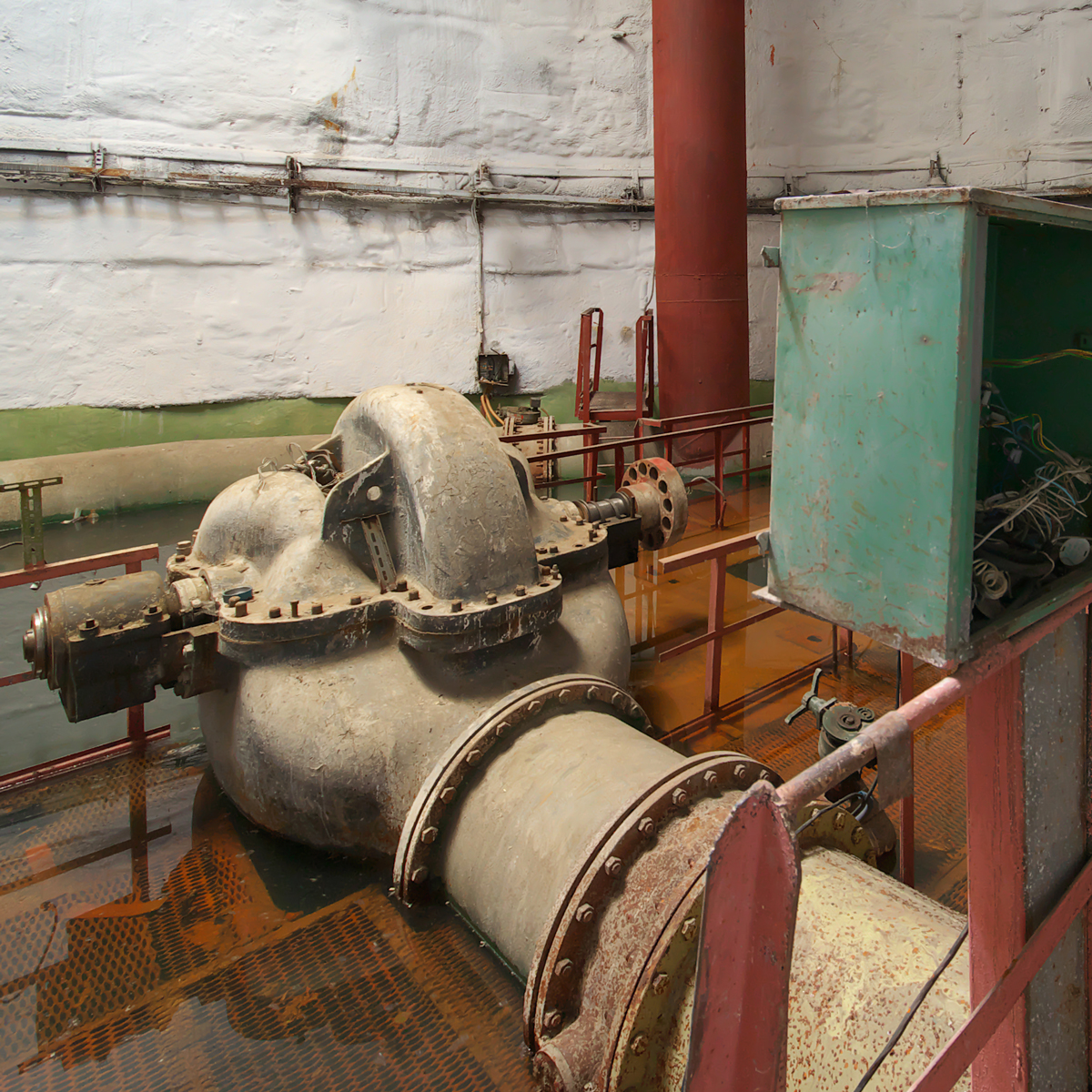

Metallic pipelines typically rust from the inside out, forming scale deposits and tuberculation on the inside of the piping itself. This (scale) build up reduces the inside diameter of the pipeline, makes flow inefficient, does not allow the piping to self-clean, and can lead to recurrent blockages. To manage this, we will offer de-scaling services to rid the system of buildup, restoring the I.D. and bringing the piping to its most serviceable state, allowing it to self-clean/self-scour with normal use.

This process is completed with high-speed rotary equipment which utilizes diamond tipped chains to incrementally remove the scale/buildup on the interior of the pipelines. Once the majority of the scale has been removed, we switch to different polishing heads to ensure a smooth finish. The entire process is camera-aided to both ensure the efficiency of our work and manage risk (ie if the scale is the only thing holding the pipeline together, we have the ability to cease operations so a repair/rehab plan can be put into place before proceeding). These services are often coupled with our high-pressure jetting and vacuum services to reclaim/evacuate the scale as it is being removed, preventing it from being sent through the system downstream.

High-Pressure Jetting

Another efficient way to clean pipelines and remove blockages is via high-pressure jetting or hydro-jetting. This is essentially a pressure washer for the inside of a pipeline/conduit. We will offer these services for the entire range of diameters, and are equipped with different types of specialty heads to perform various functions (line opening, flushing, penetrating, scale removal, root cutting, evacuation of debris/rock/sand, etc.) and have full control over our volumes (gal/min) and pressures (psi). Similar to our de-scaling services, this service is also camera-aided and often coupled with vacuum services to collect resulting debris removed from the system.

Conventional Cleaning

Caliber Restoration also has conventional line cleaning/opening capabilities which can be implemented where conditions require. These services utilize a range of commercial drain machines (snakes). Our team knows how to work in all environments (interior, exterior, office, etc.) and will manage safety, cleanliness, and limit the disturbance to the daily activities of the clients’ staff. While this service is centered around more conventional equipment, it is always paired with video inspection digital location services (although mechanically, the way the equipment works it cannot be completed at the same time as with our other services listed above).

Vacuum Services

For heavy debris, spills, storm aftermath, line breaks, etc., Caliber Restoration will offer vacuum services for pipeline and structure/inlet/culvert cleaning. These services cover the range of diameters listed above. Where conditions require (ie excavations where numerous utilities are present), this same equipment can be used to excavate (in conjunction with high-pressure air or water) to safely dig around utilities or in hard to access areas. All resulting spoils are then hauled off and disposed of off site and replaced with new upon project completion.